Aluminum Anodizing

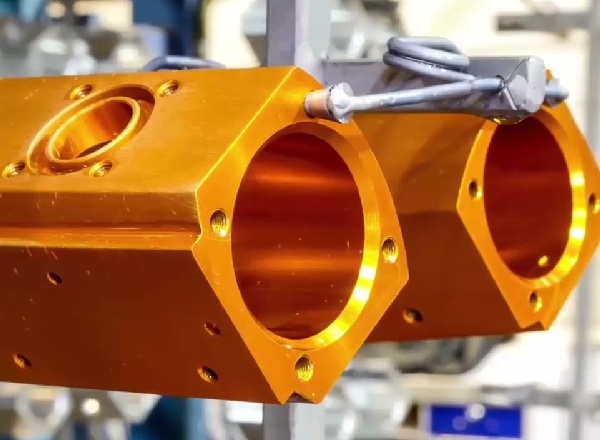

Give Your Projects A Gleaming New Look With Anodizing Aliminum

What Is Aluminum Anodizing?

Aluminum anodizing is a process that creates a protective oxide layer on the surface(substrate) of aluminum. This process involves immersing the aluminum into a chemical solution and passing an electrical current through it, which actually results in the formation of a layer of aluminum oxide on the (substrate)surface.

The thickness of this oxide layer can vary from a few microns – tens of microns depending on the actual requirements of the application. Anodizing enhances the properties of aluminum by improving its corrosion resistance, durability, and aesthetic appeal. This process is commonly utilized in a wide range of industries, including automotive, aerospace, construction, & electronics.

From Automotive To Industrial - Professional Plating For All Applications

Durability

Anodized aluminum is highly resistant to corrosion, wear, and abrasion. This really makes it ideal for use in harsh environments & applications where the material needs to withstand wear and tear.

Appearance

Anodizing can enhance the natural appearance of aluminum or give it a specific color or finish. It can also improve the metal's reflectivity & make it more resistant to fading & discoloration.

Versatility

Aluminum anodizing can be used to create a wide range of surface finishes, including matte, satin, gloss, and texture. This actually makes it a versatile option for various applications, such as architecture, automotive, electronics, and aerospace.

Eco-friendliness

Anodizing is a relatively environmentally-friendly process that produces little waste and uses fewer resources than other surface treatments, such as painting or plating.

Cost-effectiveness

Anodizing is generally a more cost-effective option than other surface treatments, as it requires fewer processing steps and materials. It also prolongs the lifespan of aluminum parts, reducing maintenance and replacement costs in the long run.

How Does The Aluminum Anodizing Process Work?

The aluminum anodizing process involves creating a layer of oxide on the surface(substrate) of the aluminum through an electrochemical reaction. This layer is not only aesthetically pleasing, but it also increases the durability, corrosion resistance, and scratch resistance of the aluminum.

To start the process the aluminum is cleaned and prepared for anodizing. It is then placed in an electrolytic bath & an electric current is passed through the aluminum and the electrolyte solution. This causes the surface of the aluminum to oxidize and create a porous layer.

The Different Types Of Aluminum Anodizing

1. Sulfuric acid anodizing, which uses an electrolyte solution to create a durable and corrosion-resistant oxide layer on the surface of the aluminum.

2. Hardcoat anodizing, also known as Type III anodizing, is a more robust process that creates an even thicker oxide layer. This type of anodizing is often used for military and aerospace applications.

3. Chromic acid anodizing is a less common process that uses a chromic acid solution to create a thin and decorative oxide layer on the aluminum surface. Other types of aluminum anodizing include

4. Two-step anodizing, which involves a pre-treatment step to enhance the adhesion of the oxide layer, and electroless nickel plating, which provides additional corrosion resistance.

What Are The Applications Of Aluminum Anodizing?

Aluminum anodizing services are widely used in a variety of industries, including aerospace, automotive, electronics, & construction. Anodized aluminum has many beneficial properties, including increased durability, corrosion resistance, and a longer lifespan.

These qualities make anodized aluminum an ideal material for components that require frequent exposure to harsh environments or that require a high level of aesthetic appeal. Common applications include aerospace components, automotive parts, architectural finishes, consumer products, and more.

With the ability to customize colors and finishes, anodized aluminum is also popular in the production of jewelry and fashion accessories. The versatility and durability of anodized aluminum make it a preferred material in many industries.

We Use The Highest Quality Electroplating Metal

Our Zinc Alloys conform to SHG (Super High Grade) or Z1 Grades with 99.995% purity.

Bring your Project to Life!

Find a metal finishing solution that best meets your needs.

How Much Does Aluminum Anodizing Cost?

The cost of aluminum anodizing services can really vary depending on distinct factors, such as the size & shape of the aluminum part, the complexity of the anodizing process, and the type of finish desired.

Typically, the cost is estimated based on the surface area of the part being anodized and the desired thickness of the anodized layer. Additionally, the cost may be impacted by any necessary preparation or finishing steps, such as polishing or coating.

While it is really difficult to give an exact cost without knowing the specifics of the project, Excel Plating offers free quotes and consultations to help determine the cost.

Step Up Your Finish

When it comes to aluminum anodizing services, you want a company that is experienced, knowledgeable, & committed to quality. Excel Plating ticks all those boxes & more. We have years of genuine expertise working with various industries, including aerospace, automotive, & consumer goods, & have an amazing track record of delivering exceptional results.

Our accomplished team is made up of experts who are truly passionate about their work & take pride in what they do. We use the latest equipment & technology to ensure the highest quality anodizing services possible. Plus, we offer competitive pricing & quick turnaround times, so you can really trust us to meet your deadlines and budget requirements.

Choose our Excel Plating for your Anodizing Aluminum needs, & experience the difference that comes from working with a robust team of professionals who care about your success.